Injection molding machine is also known as injection molding machine or injection machine. Injection molding machine is the main molding equipment that uses thermoplastic or thermosetting plastics to make various shapes of plastic products using plastic molding dies. Divided into vertical, horizontal, all-electric. The injection molding machine can heat the plastic and apply high pressure to the molten plastic to make it eject and fill the mold cavity.

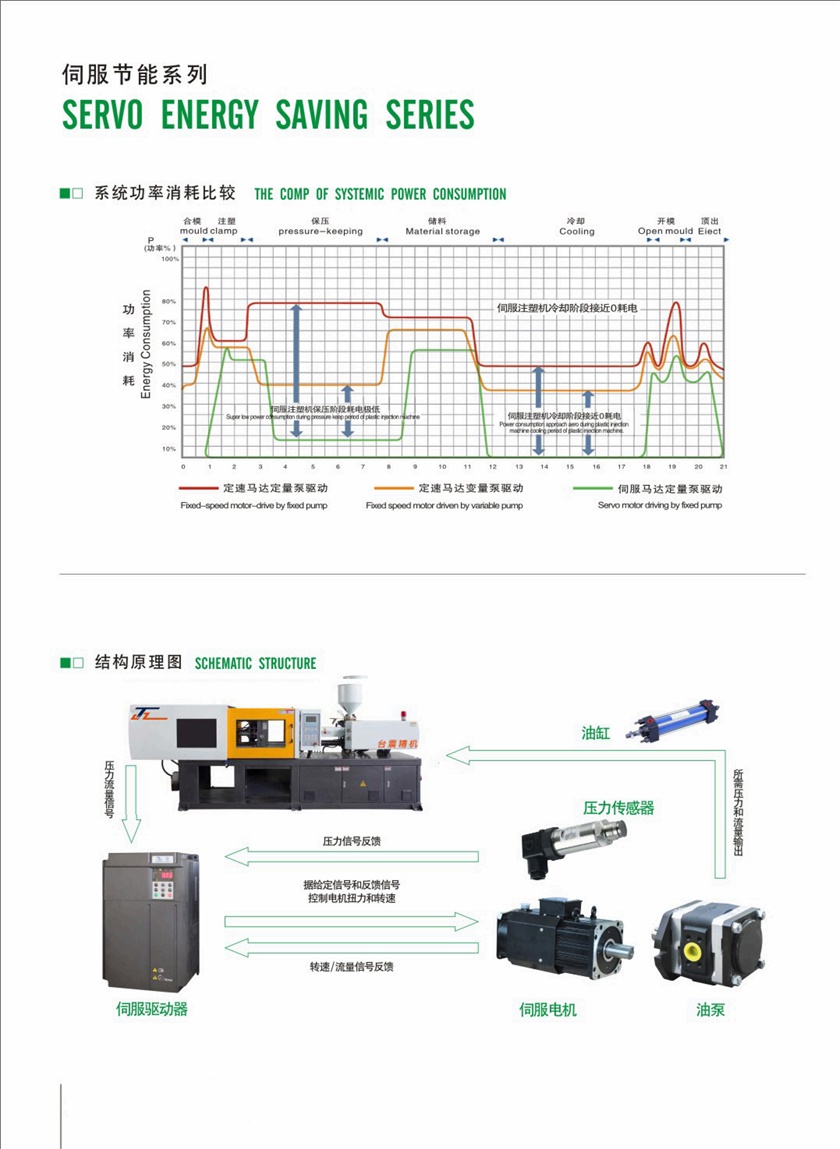

The energy saving of injection molding machine can be divided into two parts: one is the power part and the other is the heating part.

Energy saving of the power part: Most of the inverters are used. The energy saving method is to save the remaining energy consumption of the motor. For example, the actual power of the motor is 50Hz, and you only need 30Hz in production to suffice. Wasted, the inverter is to change the power output of the motor to achieve energy saving effects.

Energy saving in heating part: Most of the energy saving in heating part uses electromagnetic heater to save energy, and the energy saving rate is about 30% -70% of the old-style resistance coil.

1. Compared with resistance heating, the electromagnetic heater has an additional insulation layer, which increases the utilization of thermal energy.

2. Compared with resistance heating, the electromagnetic heater directly acts on the heating of the tube, reducing the heat loss of heat transfer.

3. Compared with resistance heating, the heating speed of the electromagnetic heater is more than a quarter faster, reducing the heating time.

4. Compared with resistance heating, the heating speed of the electromagnetic heater is faster, and the production efficiency is improved. The motor is in a saturated state, and the injection molding machine reduces the power loss caused by high power and low demand.

The above four points are why Feiru electromagnetic heaters can save energy on injection molding machines by as much as 30% -70%.

Home

Home About

About Product

Product

Album

Album Message

Message News

News Contact

Contact

address:No.138, Yangxin District, Yangkengtang, Dalang Town, Dongguan City

address:No.138, Yangxin District, Yangkengtang, Dalang Town, Dongguan City phone:0769-83120018 / 13922901799

phone:0769-83120018 / 13922901799 QQ:2284333593

QQ:2284333593